For any successful company that develops products with the highest quality standards in mind, settling for a single way of accomplishing the desired output ignores the fact that technological advancements are marching forward throughout the rest of the industry. To maintain a commitment to quality, companies must consider innovations in all aspects of their products. Elliot Equipment Company is an excellent example of this, and in this case study, specifically because of their implementation of Data Panel Corporation’s passive xtremeDB® portfolio.

xtremeDB is a family of 10-port power and signal distribution devices designed to be CANBUS I/O modules or controllers (compatible with CAN J1939 or CANopen communication protocols) or passive modules with the simple goal of improving connectivity, splitting CAN messages, or rerouting repetitive signals. Fully potted and designed with DEUTSCH ports, the xtremeDB is the most robust module in its class of devices, rated IP67 (or IP69K with Murrelektronik MDC). Recently, Data Panel and Murrelektronik released the xtremeDBm, which is a 6-port version of the xtremeDB without the 18-pin connector and with software-integrated modularity.

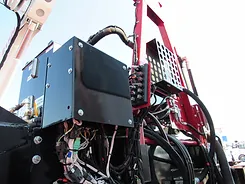

Before implementing the xtremeDB, Elliot, like many original equipment manufacturers in the material handling industry, relied on traditional wiring harnesses for their electrical systems. Wiring harnesses have been a staple in the automotive industry for decades, but what works in the engine compartments for on-highway vehicles does not always translate well to more mission specific machinery. Among some of the persistent issues with wiring harnesses is their lack of durability—environmental conditions, mediums, and even high pressure cleanings can all damage the integrity of a harness. This means the wires must be elaborately braided, bandaged, or laid in protective hoses, all of which require time and incur costs.

Another issue presented by a wiring harness’ lack of durability is that, when one of the many wiring splices is incorrect or damaged, troubleshooting and serviceability are difficult and time consuming, both of which can harm customer trust and add to the already significant hidden costs of relying solely on a wiring harness.

Other benefits of simplifying harnesses include the reduction of wires used, which has obvious and immediate impacts on cost, and the ability to future-proof the machine. Cited as an important factor in the xtremeDB passive block’s capabilities, the 18-pin connector, when populated, makes the addition of future options much easier than having to reinvent the entire system next time there is another technological improvement.

“[xtremeDB is] like a Lego set,” Jason said. “From a Bill of Material standpoint, we increased the quantity of harnesses that we need on a machine than if we designed everything into one harness, but the harnesses we do use have less wires, less splices, and are less complicated to build and troubleshoot.”

Perhaps the only drawback to using the xtremeDB has been that not all applications have a use for all ten ports. This is the case for Elliot, and when there’s a shortage in connectors to plug unused ports, this can present a problem. This exact issue is why Data Panel developed the xtremeDBm, and seeing immediately its value to Elliot’s systems, Jason said, “I am looking forward to implementing the xtremeDBm series, as that footprint fits our needs better in multiple applications on the machine.”

The trademark DEUTSCH is owned by the TE Connectivity Ltd. family of companies.